Products

Gravure Simulator

From the pressroom, you have access to a press capable of printing up to 8 colors on reel to reel or cutter creaser configuration.

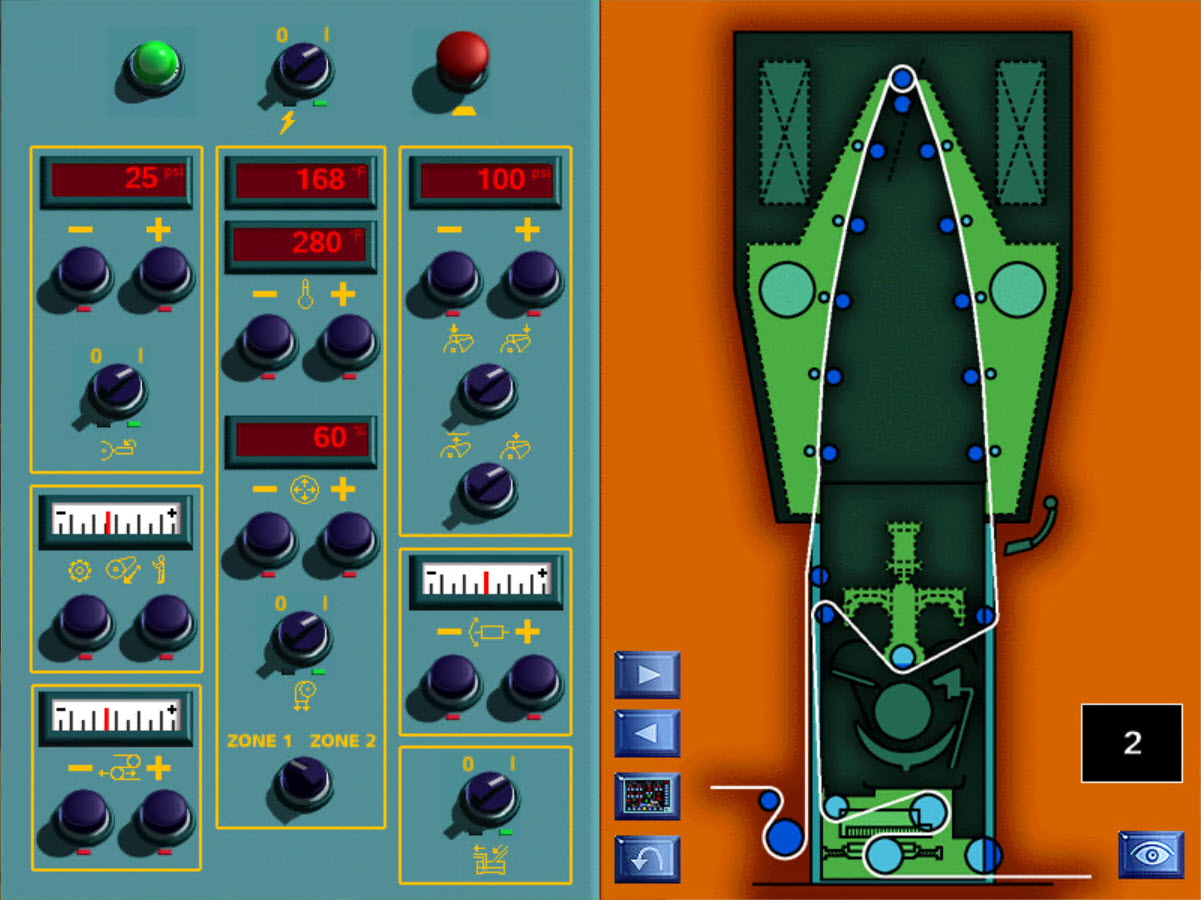

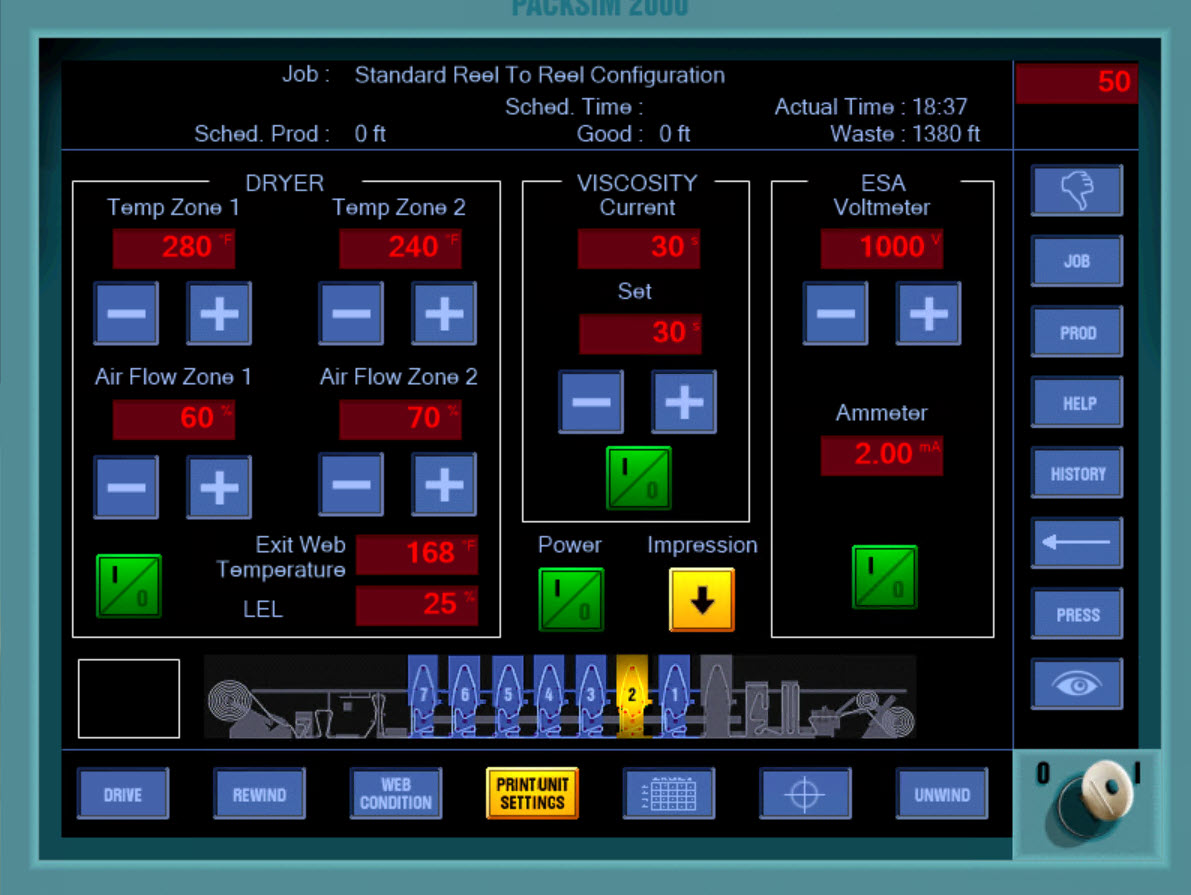

The central console is a control system with 7 screens, each controlling different simulator functions.

7 screens

8 colors

Review section

Gravure Simulator

Start screen

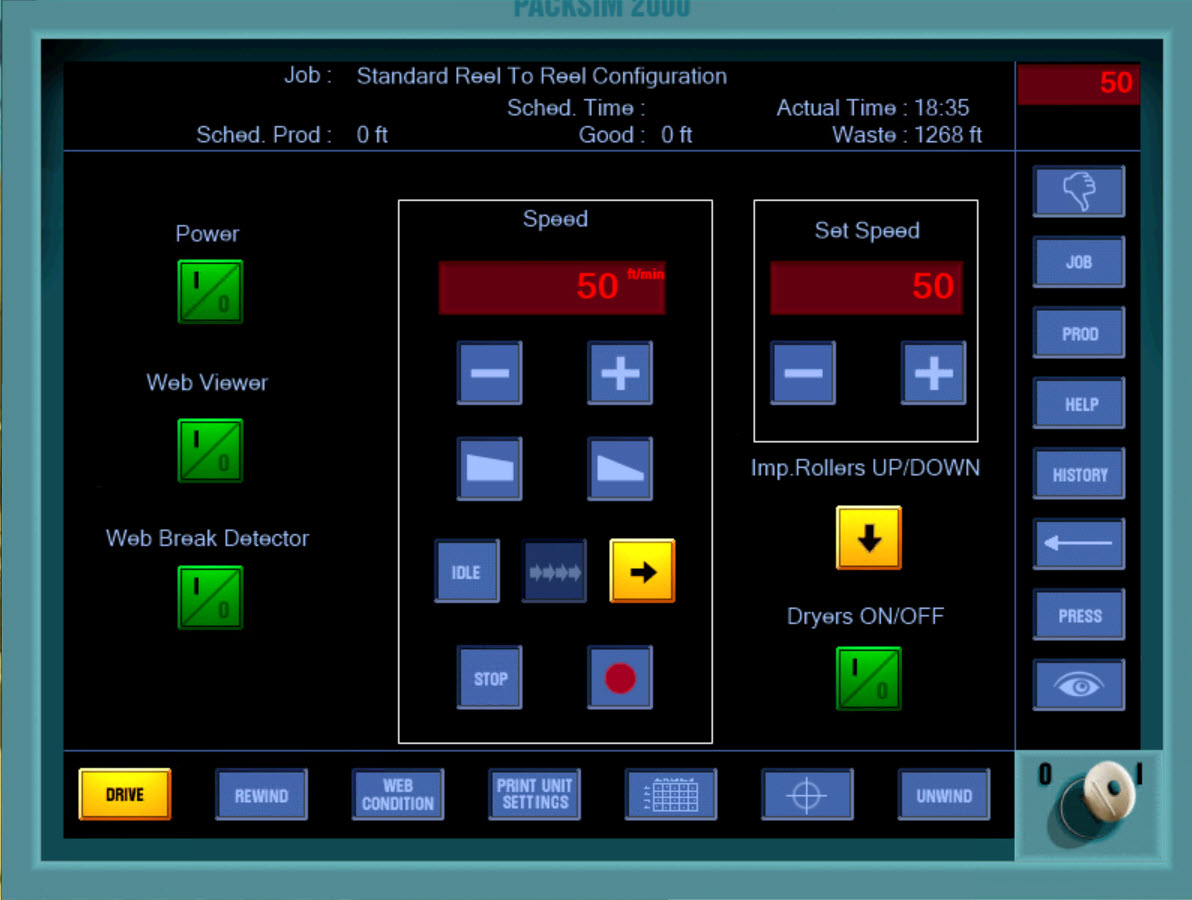

From the "drive panel" screen, you can start the press and go to the copy desk to get a new print copy.

Print copy

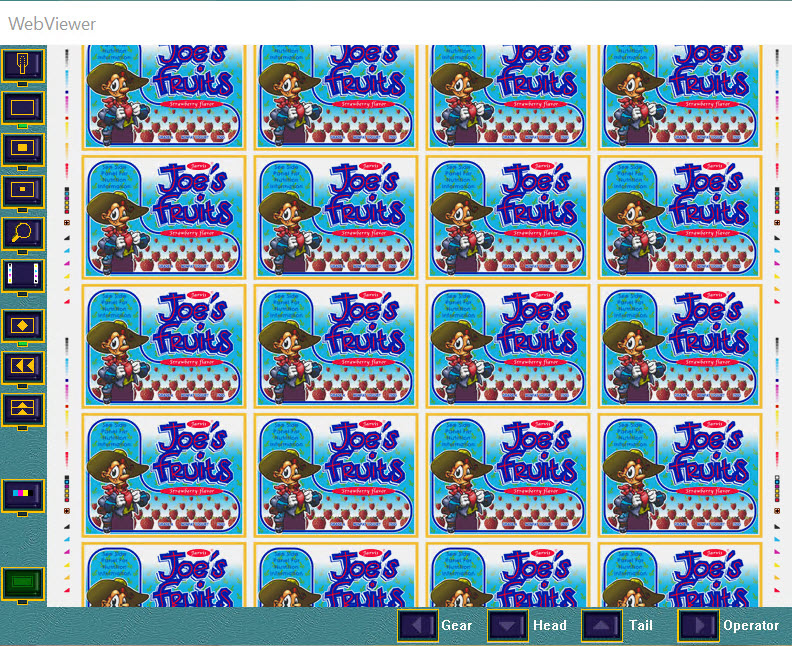

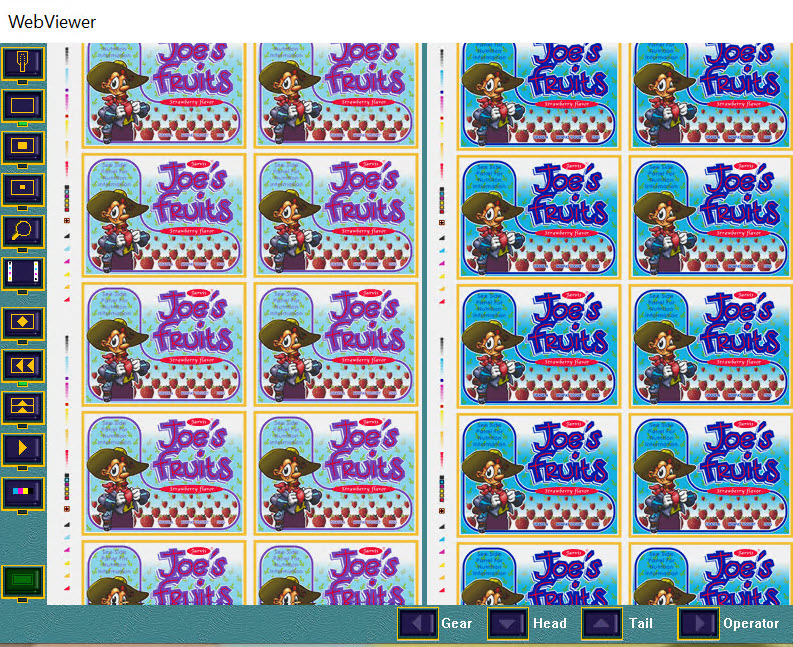

The web viewer is application in the simulator to view the printed images.

Just like on a real press, each time changes are made, a new print must be produced, and a new print copy collected to view.

Just like on a real press, each time changes are made, a new print must be produced, and a new print copy collected to view.

Function

Gravure Simulator

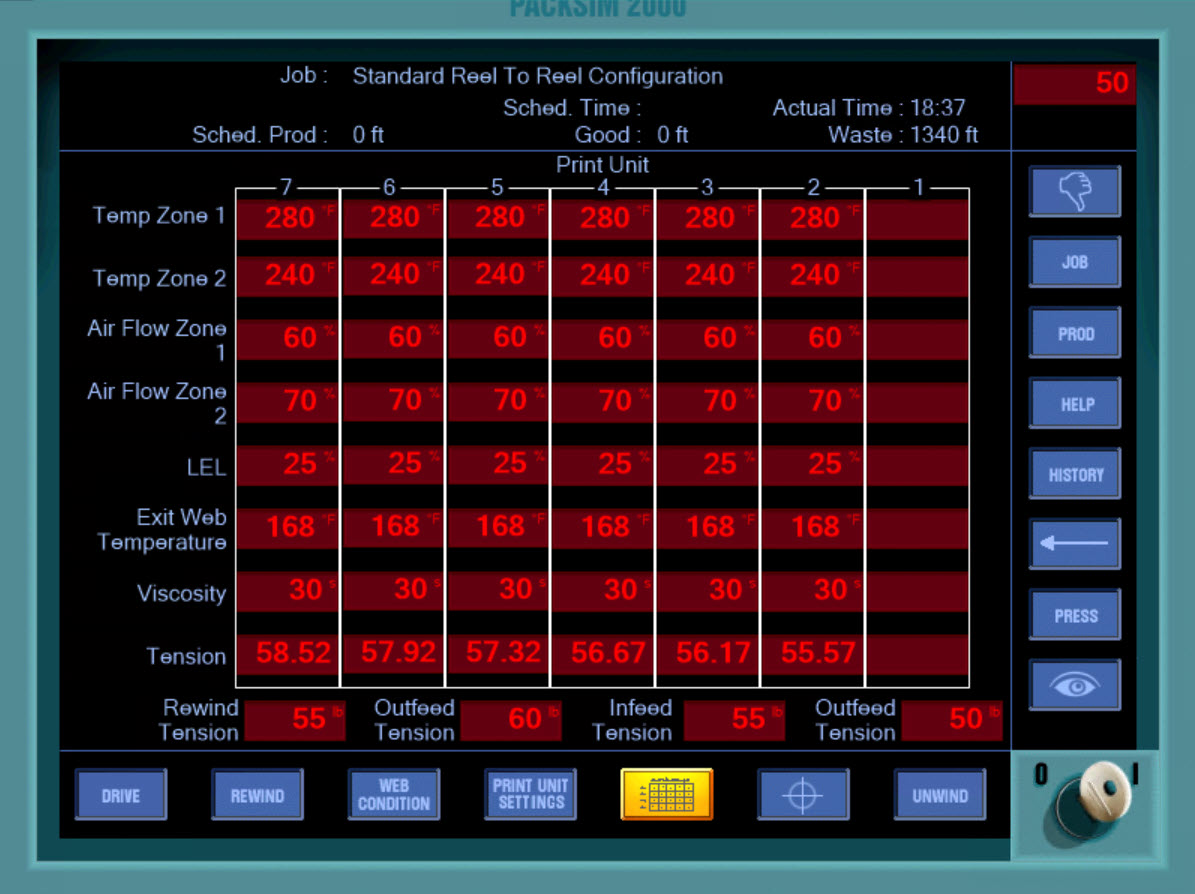

This panel shows for each unit in turn the dryer temperature, air-flow, LEL level, exit web temperatures, viscosity and web tensions.

This panel acts as a quick reference point, to check the press status at any time.

This panel acts as a quick reference point, to check the press status at any time.

From this panel, you can adjust most of parameter on printing unit such as viscosity, drying temperature…

Copy desk

Gravure Simulator

Print and ref

The web viewer is a key part of the simulator, not only displaying the current printed image, but allowing it to be viewed as a larger image, view both sides of web, directly compared print copy to a color OK copy that it must match (sometimes called print proof or contract proof), and also allows the use of five essential tools to view and measure print details.

Magnifier

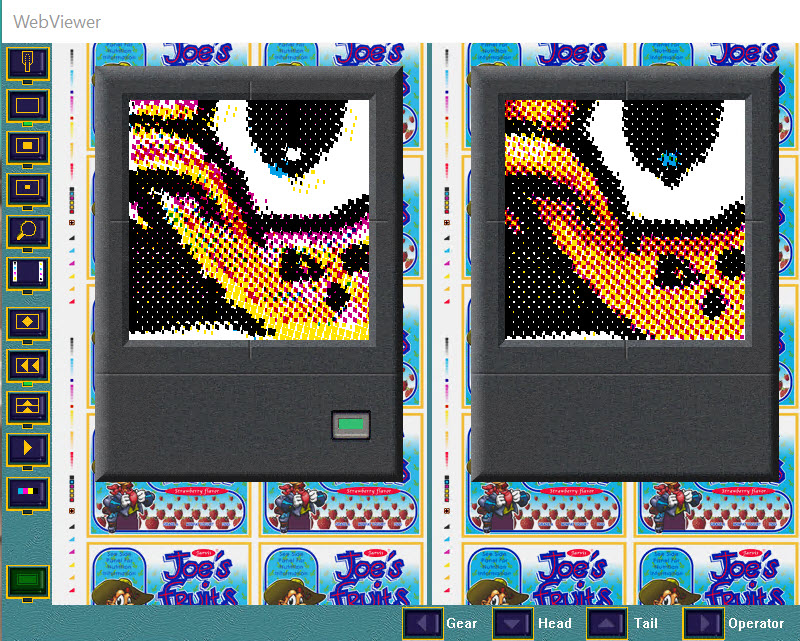

Registration is a key parameter in all forms of printing, and one of the most basic types of print fault.

Printing relies on the use of multiple colors in combination to make up images and colors.

They should be printed in the correct position relative to each other, for the image to be clear and sharp, with a true color reproduction.

Printing relies on the use of multiple colors in combination to make up images and colors.

They should be printed in the correct position relative to each other, for the image to be clear and sharp, with a true color reproduction.